Derbyshire Police prosecuted for failing to protect officers

Derbyshire Police has been fined £60,000 after several of its officers were injured when a riot training exercise went wrong.

Four serving police officers suffered burns after petrol bombs were thrown at them during the simulated exercise at a training facility in Rotherham on 2 February 2021.

An investigation into the incident by the Health and Safety Executive (HSE) found that the officers had been exposed to significant and avoidable risks during the exercise.

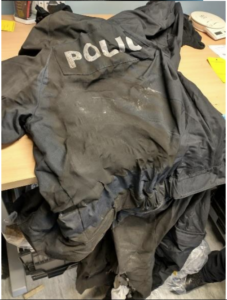

Officers wearing flame-retardant personal protective equipment (PPE) had been required to face petrol bombs thrown by other officers as part of a training drill intended to replicate a public disorder situation.

However, it resulted in four of the 13 officers taking part sustaining burns to their lower bodies, three of whom required hospital treatment. All four have since returned to work, but the incident resulted in permanent scarring, and psychological harm which will have a lasting effect.

The HSE investigation found that Derbyshire Constabulary had failed to properly plan and risk assess the exercise. Key failings included:

- Failing to give officers adequate information on the lifespan, care, and inspection of the flame retardant PPE to ensure it provided adequate protection.

- Failing to carry out a suitable and sufficient risk assessment for both the production and deployment of petrol bombs during the training.

- Failing to implement safe systems of work to control the foreseeable risks created in the course of petrol reception training.

Derbyshire Constabulary of Butterley Hall, Ripley, Derby, pleaded guilty to breaching Section 2(1) of The Health and Safety at Work etc. Act 1974. They were fined £60,000 and ordered to pay £9,470 in costs at Sheffield Magistrates Court on 19 January 2026

After the hearing, HSE Inspector Jennifer Elsegood, said: “Being a serving police officer is a job that carries with it levels of risk, however while preparing officers for dangerous situations is important, it must never come at the expense of their safety.

“High‑risk training activities must be planned and controlled with the same care and professionalism expected in any other workplace.

“The risks created by the training should have been identified as part of the Constabulary’s risk assessments and appropriately controlled.

“We hope this case reinforces the importance of thorough risk assessment, robust equipment assurance, and safeguarding those who put themselves forward to protect the public.”

This HSE prosecution was brought by senior enforcement lawyer Robert James and paralegal officer Rebecca Withell.

Further information:

- The Health and Safety Executive (HSE) is Britain’s national regulator for workplace health and safety. We are dedicated to protecting people and places, and helping everyone lead safer and healthier lives.

- More information about the legislation referred to in this case is available.

- Further details on the latest HSE news releases is available.

- HSE does not pass sentences, set guidelines or collect any fines imposed. Relevant sentencing guidelines must be followed unless the court is satisfied that it would be contrary to the interests of justice to do so. The sentencing guidelines for health and safety offences can be found here.