TATA Steel fined £1.5 million after father-of-three crushed to death at Port Talbot plant

- Grandfather Justin Day would have turned 50 this year

- Family says their world has been “shattered”

- HSE guidance on safe use of equipment is available

Tata Steel has been fined £1.5 million following the death of a contractor at its Port Talbot steelworks plant.

Justin Day’s family learnt of his death while they were waiting for him at his youngest son’s school rugby match.

The much-loved father-of-three and grandfather was working at the steel manufacturer’s site in South Wales when he was crushed to death by a piece of machinery on 25 September 2019.

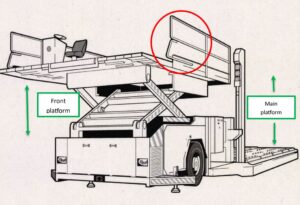

Maintenance work to replace a lift cylinder on a large conveyor system had been completed earlier that day, and the system was in the process of being put back into service when a hydraulic leak was found. A radio call was sent out for Justin, 44, to resolve the issue at about 2pm.

Although power was isolated to part of the system, other sections remained live. As staff worked on the lower level to fix the leak, Justin returned to the floor above and climbed into the conveyor system. His presence triggered sensors that activated a moving beam in a live section, fatally injuring him. He was sadly pronounced dead at the scene.

Tata Steel failed to ensure the conveyor system was properly isolated and guarded. The company did not take sufficient steps to manage the safety of the ongoing work.

The Health and Safety Executive (HSE) investigated Justin’s death and brought a prosecution against Tata for what an inspector described as “basic” health and safety failures.

At the time Tata’s Port Talbot plant was the largest steelworks in the UK. Earlier this month, construction started on Tata’s electric arc furnace (EAF) at the same site.

Justin Day’s family had been waiting for him at the rugby field that afternoon, ready to watch his youngest son play in a school match. But instead, they received a devastating phone call telling them he had been involved in an accident. Just an hour later, they learned he had been killed.

Justin would have turned 50 this year. His wife Zoe Day said rugby was his passion, and that when his sons played, he was their “biggest fan”. She “never imagined” to be given the news of the incident while waiting for him to arrive pitch side.

“Since losing Justin I am not the same person I was,” she said. “I have struggled since that day – mentally, I am lost and don’t know where I’m going with life. It’s shattered my whole world.

“We were together for 23 years and did everything together. I can’t put into words how much this has affected me. I am a shadow of my former self and from the day of the incident, my world fell apart.”

The HSE investigation into the incident found Tata Steel failed to ensure the work to replace the lift cylinder was done safely. After the job was completed, the company also failed to properly isolate the conveyor system before Justin returned to address the leak.

Tata Steel also failed to ensure the conveyor system was effectively guarded to prevent access to dangerous moving parts of the machinery.

Tata Steel (UK) Ltd, of Grosvenor Place, London, pleaded guilty to breaching Sections 2(1) and 3(1) of the Health and Safety at Work etc. Act 1974. The company was fined £1.5 million and ordered to pay £26,318.67 in costs at Swansea Crown Court on 31st July 2025.

HSE inspector Gethyn Jones said: “Justin Day’s death could so easily have been prevented. A much-loved family man is not here because of failures in health and safety basics.

“Employers have a responsibility to make sure sufficient procedures are in place to protect workers – both employees and contractors – and that those procedures are understood and followed.

“The dangers of moving machinery are well known. Sufficient risk assessments must be carried out and access to dangerous areas must be properly guarded and controlled.

“This has been a long and thorough investigation, and we believe this is the right outcome. It is clear that Justin’s death has had a devastating impact on his family, his friends and the wider community. Our thoughts remain with them.”

HSE guidance on the safe use of work equipment is available on our website: Safe use of work equipment – HSE

This prosecution was brought by senior enforcement lawyer Jon Mack at HSE.