Waste firm fined after worker crushed by excavator

A County Durham waste management company has been fined after a young employee was run over by an excavator.

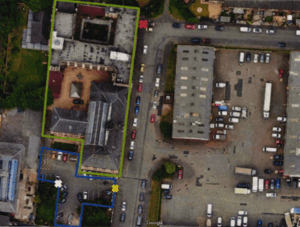

Farm XS (Northern) Limited, based in Barnard Castle, was sentenced after an incident on 29 January 2024 that left the 24-year-old with serious injuries.

The employee was only in his second week of employment at the Staindrop Road site when he was struck from behind by an excavator and run over. He suffered fractures to both feet.

An investigation by the Health and Safety Executive (HSE) found that the company had failed to ensure a safe system of work was in place. The 24-year-old was working on a waste pile near moving vehicles with no physical separation between them. There was no risk assessment or system of work to protect pedestrians from vehicle movements.

HSE guidance clearly states that pedestrians and vehicles should be segregated when waste is being manually sorted. By law, employers must ensure traffic routes can be used without risking the safety of workers nearby. Guidance is available at hse.gov.uk – Transport movements – HSE

The case against Farm XS (Northern) Limited, Shaw Bank, Staindrop Road, Barnard Castle, County Durham, DL12 8TD, was heard at Teesside Magistrates’ Court on Tuesday 5 August 2025. The company pleaded guilty to breaching Section 2(1) of the Health and Safety at Work etc. Act 1974.It was fined £4,000 and ordered to pay £4,285 in costs.

After the hearing, HSE inspector Richard McMullen said:

“The outcome could have been much worse. But the failures that day meant a worker received serious injuries.

“This incident was easily avoidable by implementing control measures and safe practices to ensure that workers were not put at risk from moving vehicles, including clear segregation and safe refuges.

“This should be a reminder to the waste industry of the need to consider workplace transport risks and to introduce appropriate control measures to separate vehicles and pedestrians.”

This prosecution was brought by HSE enforcement lawyer Iain Jordan and paralegal officer Helen Jacob.

Notes to editors

- The Health and Safety Executive (HSE) is Britain’s national regulator for workplace health and safety. We prevent work-related death, injury and ill health through regulatory actions that range from influencing behaviours across whole industry sectors through to targeted interventions on individual businesses. These activities are supported by globally recognised scientific expertise. hse.gov.uk

- More about the legislation referred to in this case can be found at: legislation.gov.uk

- HSE news releases are available at: hse.gov.uk

- Guidance for working safely with vehicles can be found at: Workplace transport – HSE